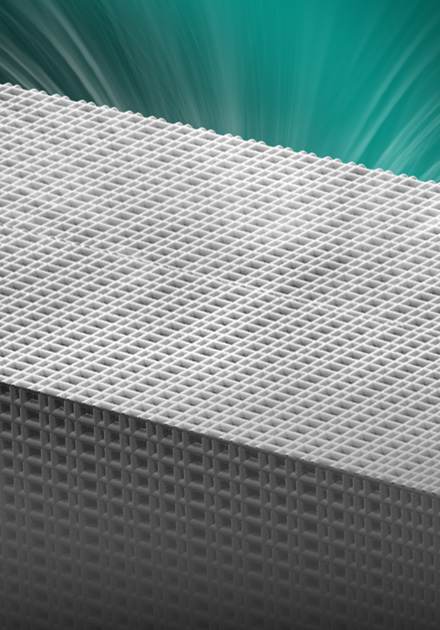

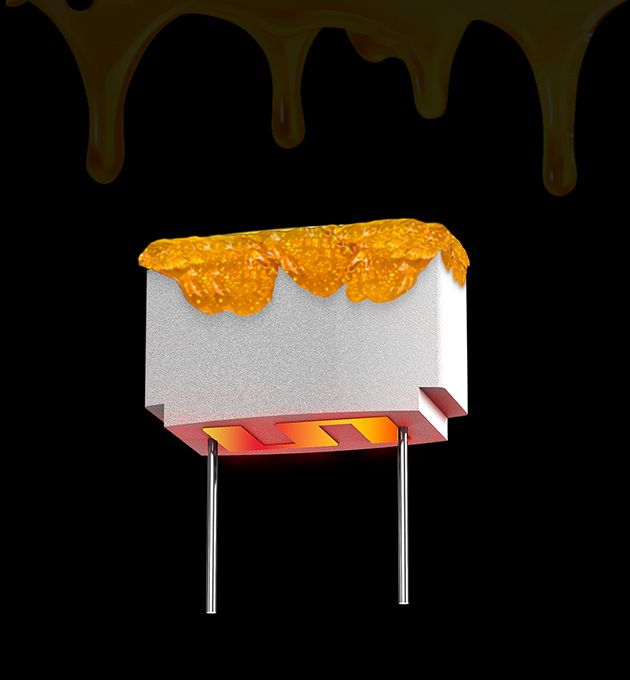

Lock Oil

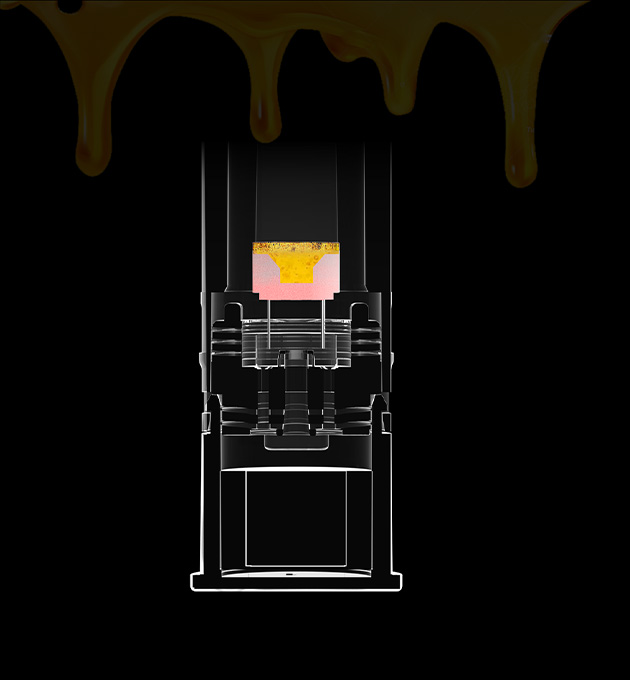

Better Leakage Prevention

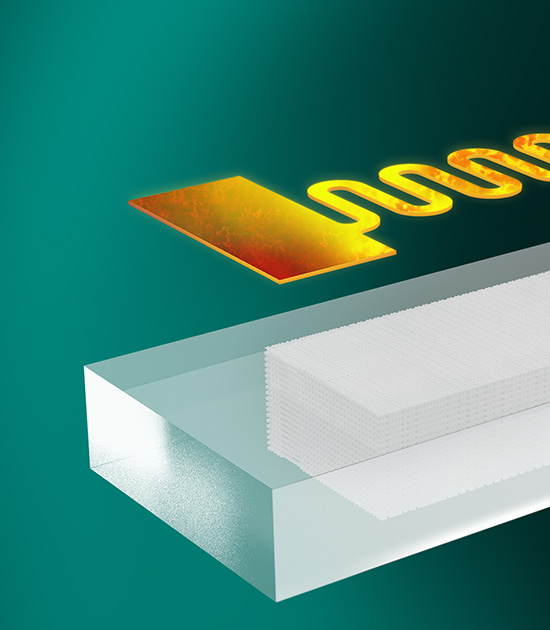

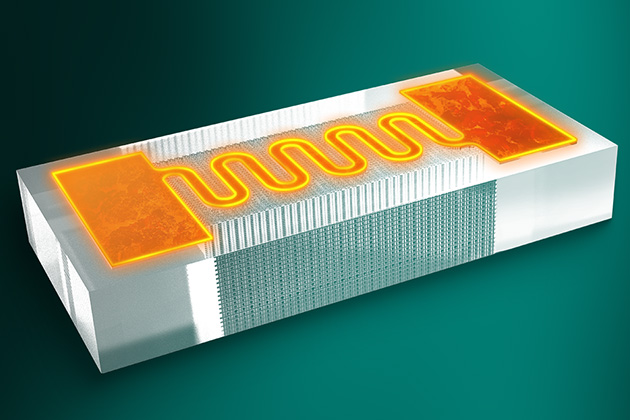

Ultra-Stable Ohm Performance

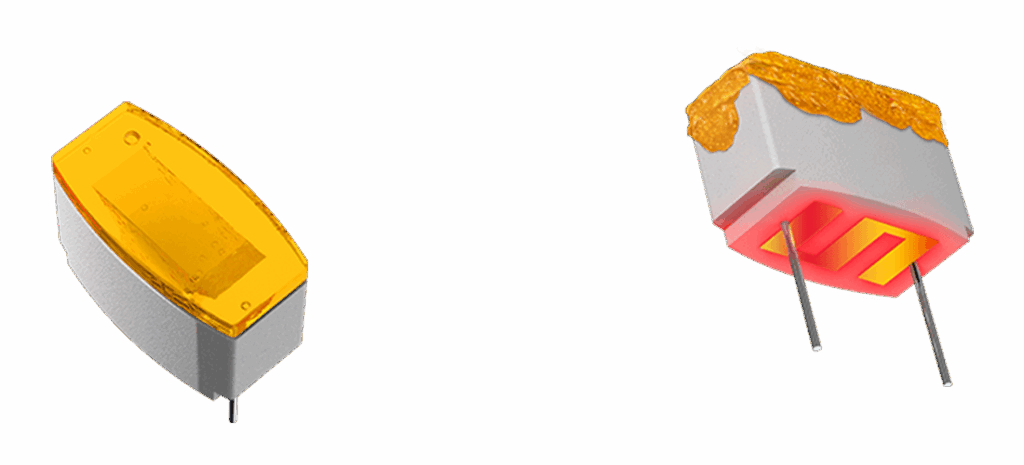

Integrated Electrode Design

Designed with a higher-volume, thicker ceramic matrix, our core increases oil absorption across every microporous channel.

Lower Condensation

Smarter Heating Layout

Nextvapor utilizes advanced ceramic heating elements to provide stable temperature control and uniform heat distribution. This ensures efficient vaporization of cannabis oils, minimizes residue buildup, and extends coil longevity.

Chemically inert and thermally stable, ceramic cores preserve the oil’s original flavor while maintaining consistent performance across a wide range of viscosities.