Automated Filling and Capping - Automation for Your Brand

- Fast, Efficient Production with Reduced Labor

- Accurate, Precise Filling for Consistent Quality

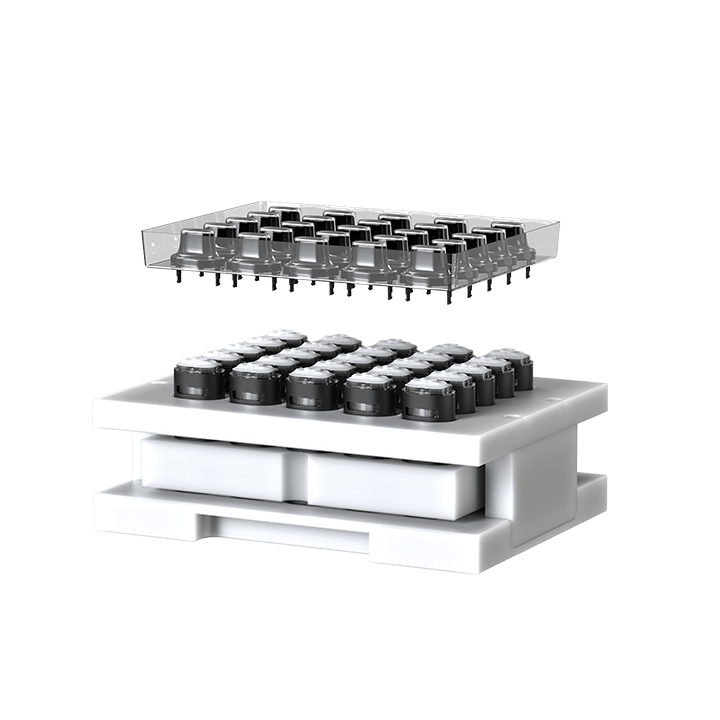

- Leak Free Capping for Reliable Performance

- Error-Free Operation with Standardized Process

- Multi-Size Compatibility for Versatile Production

- Professional High Quality Manufacturing for Brand Trust

- Clean, Safe, Hygienic Operation for Maximum Safety

-

How does the automated filling and capping system enhance production efficiency?

Nextvapor’s automated filling and capping system is engineered for high-throughput manufacturing, significantly reducing manual intervention and labor dependency. A fully standardized workflow minimizes operator variability, improves line stability, and enables consistent, repeatable production at scale. -

What level of filling accuracy and consistency can be achieved?

Nextvapor utilizes precision-controlled dispensing technology to achieve highly accurate and repeatable fill volumes. This ensures batch-to-batch consistency, reduces material loss, and supports strict quality control requirements in large-scale production environments. -

How does the capping process ensure leak prevention and device reliability?

Nextvapor’s capping process applies controlled force and precise alignment parameters to produce consistent, leak-resistant seals. This reduces sealing defects, protects product integrity, and ensures reliable performance during storage, transportation, and end use. -

Can the system accommodate multiple product sizes while maintaining safety standards?

Yes. Nextvapor’s automated platform is designed for multi-size compatibility with efficient changeover. All operations are conducted under clean, safe, and hygienic manufacturing conditions, supporting regulated production requirements and reinforcing high-quality, professional manufacturing standards. -

How does the automated system reduce operational errors and improve process reliability?

Nextvapor’s automated system is built on standardized, closed-loop process control to minimize human error. Automated parameter control and repeatable operating sequences ensure stable performance across production runs, improving yield rates, reducing rework, and maintaining consistent manufacturing quality.