Built for Precision, Purity, and Partnership

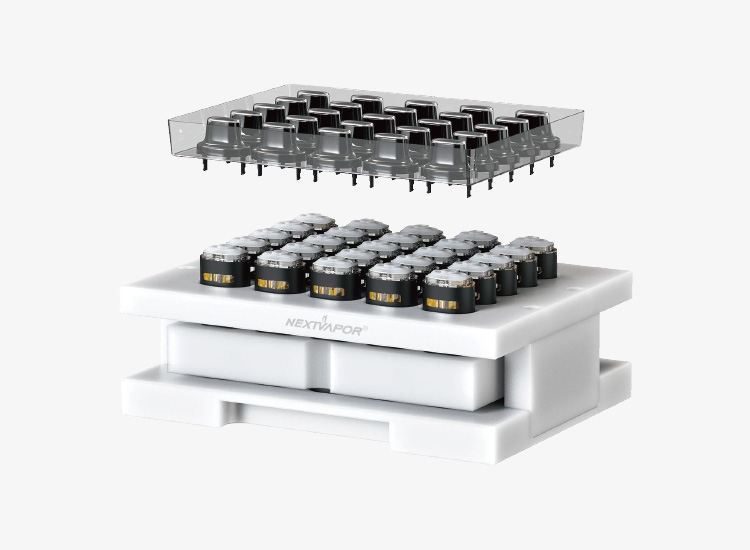

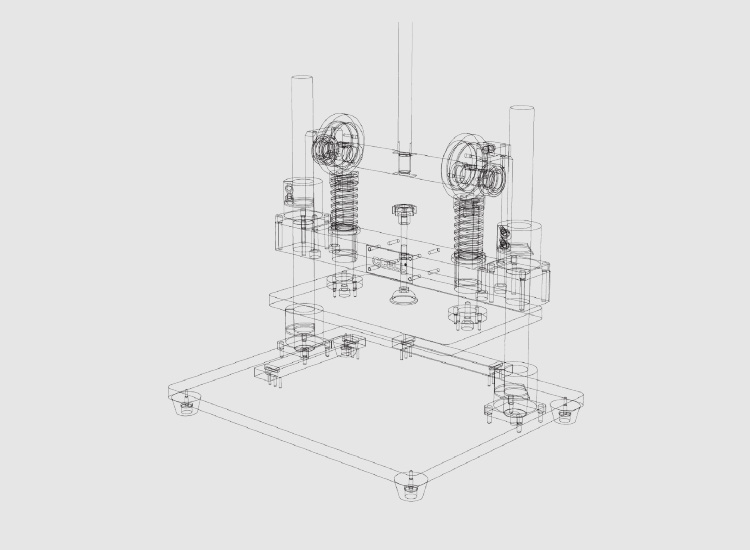

At Nextvapor, we combine cutting-edge automation with meticulous craftsmanship to deliver vape hardware that meets the highest standards. Our production lines are capable of handling both small-batch custom orders and large-scale deliveries, ensuring consistent quality and on-time fulfillment.

Driven by innovation and engineered for reliability, we deliver world-class vapor hardware that empowers brands across international markets. With precision design, durable construction, and consistently smooth performance, our solutions elevate the vaping experience and set a global benchmark for quality and innovation.

m²

Production Workshops

m²

Factory

+

Professional Employees

million

Annual Pieces

Production Workshops

Factory

Professional Employees

Annual Pieces

We inspect all incoming materials against strict specifications to ensure every component meets our quality requirements before entering production.

Air-Tightness Testing

IPQC In-Process Quality Control

During production, critical checkpoints are monitored in real time to detect issues early, ensuring process consistency and reliable output quality.

Post-Filling Standing Test

After oil filling, devices are placed under controlled conditions to observe stability, ensuring no leakage, seepage, or unexpected reactions before final assembly.

Full Appearance Inspection

Every finished unit is inspected individually for surface quality, alignment, finishing, and overall craftsmanship to ensure a flawless customer-facing product.

Rapid· Reliable· Responsible

We respond quickly to customer feedback by gathering all necessary details, including product type, batch number, and a clear description of the issue. Supporting materials such as photos or videos are collected to aid accurate evaluation. We also consider the context—whether it’s a new order, a return, or an in-use issue.

Within 24 hours of receiving the feedback, our factory team begins investigation. We determine whether the issue is batch-related or an isolated case and conduct a thorough root cause analysis.Technical evaluation is completed within 48 hours, and a comprehensive corrective action report is delivered within 72 hours—ensuring transparency and timely resolution.

We identify whether the issue originates from production, end-user handling, or upstream material supply. Sales teams offers clear usage guidance and product training as needed. For supplier-related issues, we coordinate directly with material vendors to implement quality improvements and prevent recurrence.

For complex or unclear issues where the root cause is not immediately evident, we initiate long-term tracking and continuous monitoring. We coordinate across all relevant parties—including the U.S. warehouse, factory, and suppliers—to ensure full resolution and establish preventive mechanisms.

We will contact you soon.